our services

- Consultancy & Expertise

- Engineering

- Inspection & Testing

- Valves & Safety Valves

- Training

Our experts, Technical Engineering Specialists and Engineer Surveyors provide engineering special services alongside the statutory examinations required by law. These services play a key role in managing risk, protecting people and improving operational efficiency.

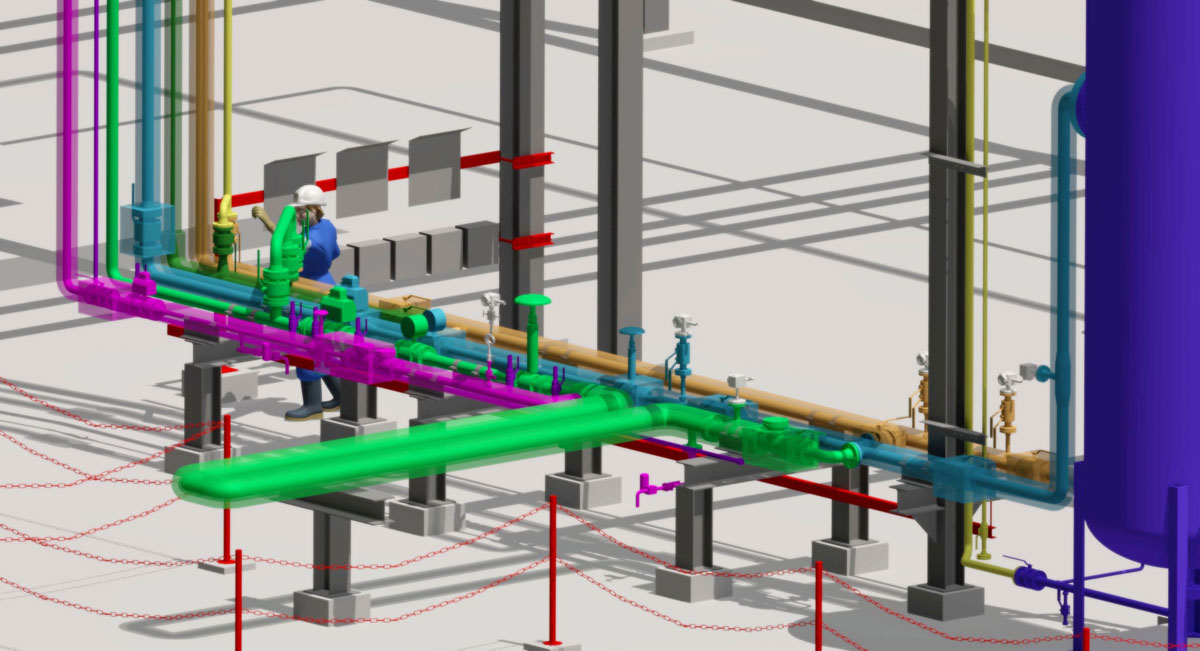

We examine everything from pressure vessels, piping, valves, control valves and safety pressure valves through out any static part on your installation.

It doesn't matter if you are commissioning new or repairing existing plant, we provide support through every stage of the design and manufacturing process. We carry out tests, conduct audits and prepare detailed reports on whether an item meets the design specification prior to being put into service. We can also conduct a ‘prior to purchase’ examination for customers if required. Our experts are recognized by international standards committees. This knowledge is invaluable when it comes to checking that work conforms to the relevant standards.

We focuses on the delivery of high-caliber engineering resource and technical assurance services across:

- Offshore and onshore oil and gas

- Power generation

- Industries and factory

- Renewable energy

Field Development Planning

M Expert Engineering offers our clients a large choice and

services starting from feed engineering to Quality

assurance/ Quality control of realized projects.

The engineering department cover multidisiplinar fields

including mechanical, material, process, elctrical,

instrumentation and automation.

Feasibility Studies

Our back office engineering staff is highly available to made all necessary estimation and simulate the feasability of you project or shut down and claculate the Cost time ressources required for realization. We conduct all necessary preparation and time management regardless the size of your project.

Conceptual Engineering

If you need more than just an ordinary engineering work this service is just what you need. At M expert engineering, we will work with you to learn the specific requirements of your process and help you simplify the exploration process. We monitor your specialized installation or equipment to ensure they are inline with your expectation.

Project Management Consultancy (PMC)

Planification and management of you shutdown, is one of the duty that we can offer. Our experienced engineering staff will be available to carry out all preparation and pre-shutdown work and provisions.

Detailed Engineering

Our multidisciplinary engineering knowledge and experience offer to our clients a large choice of detailed engineering work such Pressure vessels calculation or flaring system performance analysis. We use international standards last editions and updated software versions to fulfill with global requirements and customers specification.

Inspection and testing

We provide condition reports and structural surveys. We also carry out damage and incident investigations along with verification tests against design codes, national and international standards. Our skilled testing and calibration team can perform specialist tests such as realization of proof load testing. To complement our testing services we can also certify valves and pressure safety valves to both European and American standards.

All these services play an important part in the risk management process. By ensuring equipment meets specification and is always fit-for-purpose, we can help reduce downtime, extend plant life, improve operating efficiency and reduce operating costs.

Our skilled team has the knowledge to develop new techniques and devise cost-effective solutions for testing equipment that will save money and minimize disruption.

When a visual examination alone is not enough to ensure product integrity and reliability we have the resources to perform a full range of material tests. Certain tests will be performed on-site. For example, we have the knowledge and capability to examine in-service plant, including actuated valves, control valves PCV/ LCV, pressure safety valves PSV and pressure vacuum relief valves PVRV.

A failure will not appear until a unit has passed final inspection.

Taking Care of Your valves

M expert engineering offer a specialized maintenance of your valves including ball valves, check valves, gate valves, swing valves and choke valve either manual or actuated for a size till 24 inch and a pressure range coverage till 15000 PSI (1000 Bar). We carry out all necessary kind of maintenance including refurbishment solution and test according local legislation and applicable international standards. We move our team and equipment to your site during plant shutdown.

Pressure safety valves Maintenance and calibration

A unique feature of our full maintenance policy is that we provide replacement repair kit and spare parts allowing you to minimize downtime and business disruption. Any brand of PSV till a pressure setting of 15000 PSI, we can ensure result regardless the damage as our experienced team and repairing tools are fully suitable to make the necessary work and re-establishment of your safety valves.

We deliver best in class training content for the entire workforce within Inspection, Operations and Maintenance. With our proven training solutions we have serviced corporations in the Energy Industry, Process Industries, Industrial Manufacturing, Chemical Plants, Food and Beverage Plants, Pulp and Paper Plants, Petrochemical and Maintenance Services companies. The valve training course is designed for industrial maintenance technicians, managers, supervisors, and personnel who require knowledge on critical valve maintenance, repair, and operation procedures. This Special training course aims to take the mystery out of all aspects pertaining to valves and actuators, and to assist delegates in seamlessly going through all the important thought processes related to these devices, from selection to installation, and everything in between. Our courses will provide a total in-depth insight into valve and actuator technology, covering: control valves, check valves, shut-off valves, solenoid valves, and pressure relief valves. A methodology is presented to ensure the optimum selection of size, choice of body and trim materials, components, and ancillaries. Whilst studying both liquid and gas valve sizing, delegates will also learn the correct procedures for calculating the spring 'wind-up' or 'bench set'. Maintenance issues also include: testing for dead-band/hysteresis, stick-slip, and non-linearity; on-line diagnostics; and signature analysis. Throughout the workshop, participants will learn through active participation using exercises, questionnaires, and practical sessions covering: systems choice; basic sizing calculations; computer-based sizing; and maintenance diagnostics.